Rise of polyfunctional robots in industrial automation

The rise of polyfunctional robots in industrial automation enhances efficiency and flexibility by enabling machines to perform multiple tasks, driving innovation while addressing challenges such as integration and workforce adaptation.

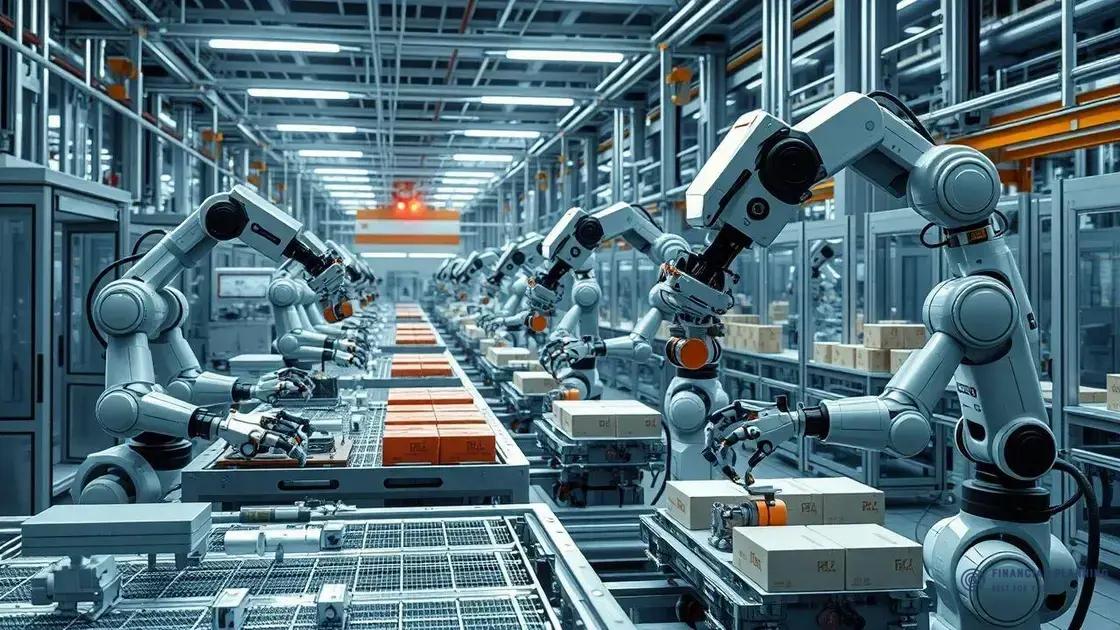

In recent years, the rise of polyfunctional robots in industrial automation has sparked significant interest. These innovative machines are not just performing repetitive tasks but adapting to various operations, enhancing efficiency. Curious about how they might reshape the future of manufacturing?

Understanding polyfunctional robots

Understanding polyfunctional robots involves recognizing their advanced capabilities and the roles they play in modern industries. These robots can perform multiple functions, making them essential in various processes. Their versatility allows them to adapt to different tasks, which is crucial in an ever-evolving industrial landscape.

What Makes Polyfunctional Robots Unique?

Polyfunctional robots differ from traditional robots in several ways. They are not confined to a single task but can switch between functions seamlessly. This adaptability leads to greater efficiency and productivity in industrial settings.

- Ability to perform various tasks

- Integration of advanced sensors and AI

- Reduced need for specialized machinery

- Improved workflow and collaboration with human workers

Furthermore, their design allows for easier integration into existing systems, which can save companies time and resources. By leveraging the latest technology, these robots can analyze data in real time, making decisions that enhance operational efficiency.

The Importance of Flexibility

The flexibility provided by polyfunctional robots is a game changer for industries. They can quickly adapt to changes in production demands without the need for extensive reprogramming. This flexibility not only speeds up production but also reduces operational costs.

As industries continue to embrace automation, understanding how polyfunctional robots function will be key. They represent a shift towards smarter manufacturing processes that prioritize efficiency and adaptability. Companies looking to maintain competitive advantages must consider investing in these innovative solutions.

Ultimately, the rise of polyfunctional robots signals a transformation in how industries operate. Embracing this technology can lead to improved productivity and a more responsive approach to manufacturing challenges.

Key benefits of polyfunctional robots in industry

Exploring the key benefits of polyfunctional robots in industry reveals how these innovative machines improve productivity and efficiency.

These robots can handle multiple tasks, which allows for a more streamlined workflow in various sectors. Their adaptability means they can seamlessly transition between different operations without significant downtime.

Increased Efficiency

One of the major advantages of polyfunctional robots is their ability to increase overall operational efficiency. By performing different functions, they reduce the need for multiple specialized machines. This leads to a leaner production environment where resources are optimized.

- Minimizing machine redundancy

- Lowering operating costs

- Enhancing speed of operations

- Facilitating better space utilization in factories

The integration of advanced technologies enables these robots to operate on multiple levels. For instance, they can perform assembly, packaging, and quality control tasks, which traditionally required multiple different machines. This capability not only saves time but also minimizes the risk of errors.

Improved Flexibility

Another substantial benefit is the flexibility these robots provide. In an industry where market needs can change rapidly, having machines that can adapt is crucial. Polyfunctional robots can be reprogrammed or reconfigured quickly to meet new requirements, allowing for swift responses to market trends.

Furthermore, they can work alongside human employees, enhancing collaboration. This blend of human intelligence and robotic efficiency results in improved outcomes and productivity on the shop floor. Workers can focus on more complex tasks while robots manage repetitive or dangerous work, ensuring safety and efficiency.

Overall, the impact of polyfunctional robots in industry is profound. They are not only reshaping how manufacturing processes work but also driving innovation in workflow management. With their versatility, these robots represent the future of industrial automation.

Factors driving the rise of polyfunctional robots

Various factors are driving the rise of polyfunctional robots in today’s industries. As companies seek greater efficiency and adaptability, these robots have become integral to modern manufacturing processes. Understanding what propels their adoption is essential for grasping the future of automation.

Technological Advancements

One major factor is the rapid advancement of technology. Innovations in artificial intelligence, machine learning, and robotics have made it possible for these machines to perform complex tasks. With the ability to learn and adapt, polyfunctional robots can handle numerous functions that were once reserved for separate specialized devices.

- Integration of AI for improved decision-making

- Enhanced sensors for accurate operation

- More efficient energy consumption

- Robust software solutions for seamless integration

These advancements are not only improving capabilities but also reducing costs associated with production. Companies can save money by using one robot for multiple tasks instead of investing in various machines.

Market Demand

Another significant driver is the growing market demand for flexibility and speed. In a competitive landscape, businesses must adapt quickly to changing consumer preferences. Polyfunctional robots offer the required agility to pivot production processes swiftly, scaling up or down based on demand.

As industries face increasing pressure to deliver quality products faster, the ability of polyfunctional robots to reconfigure easily becomes invaluable. They can shift from one task to another effortlessly, allowing manufacturers to meet tight deadlines without sacrificing quality.

Moreover, labor shortages are another key factor. With a diminishing workforce in many regions, companies are turning to polyfunctional robots to fill gaps. These robots can consistently perform tasks that might be challenging for human workers, ensuring that production remains uninterrupted.

In summary, the rise of polyfunctional robots is propelled by technological advancements, growing market demands, and the need to address workforce challenges effectively. Embracing these robots not only enhances operational efficiency but also positions companies for future success.

Challenges in adopting polyfunctional robots

Adopting polyfunctional robots comes with its own set of challenges that industries must navigate. While these robots offer numerous benefits, understanding the obstacles helps companies prepare for successful integration.

High Initial Costs

One of the most significant barriers to adoption is the high initial investment required for polyfunctional robots. Businesses may face steep upfront costs when acquiring and implementing these sophisticated machines. This includes the cost of purchasing the robots, reconfiguring existing workflows, and training staff to operate them.

- Expense of advanced robotics technology

- Investment in staff training and development

- Costs related to system integration

- Maintenance and upgrade expenses

While the long-term savings can justify the investment, the initial costs can deter many companies from making the leap. They often worry about whether the return on investment (ROI) will be worth the expense.

Integration with Existing Systems

Integrating polyfunctional robots into existing manufacturing systems presents another challenge. Many factories have established workflows and equipment, making it difficult to incorporate new technologies. It requires careful planning to ensure that robots can coexist with outdated machinery without disrupting production.

This integration may also involve extensive software compatibility checks. Companies must ensure that the new robotics systems can communicate effectively with existing technologies to maximize efficiency. If not managed properly, it may lead to inefficiencies and operational delays.

Workforce Adaptation

Another challenge lies in workforce adaptation. Employees may feel apprehensive about working alongside robotics, fearing job displacement or changes in job roles.

Providing adequate training and support is crucial in alleviating these concerns. Companies must encourage a culture that embraces technology and emphasizes the collaborative benefits of human-robot interaction.

Moreover, creating a skilled workforce capable of managing and maintaining polyfunctional robots can take time and resources. Upskilling existing employees or hiring new talent proficient in robotics is necessary to ensure ongoing success in a tech-driven environment.

In brief, while the obstacles of adopting polyfunctional robots are significant, they are manageable. Addressing high costs, ensuring system integration, and preparing the workforce can pave the way for successful implementation. Despite these challenges, the potential advantages of efficiency and adaptability make this investment worthwhile.

Future trends of polyfunctional robots in automation

The future trends of polyfunctional robots in automation promise exciting developments that can revolutionize industries. As technology progresses, these robots will continue to evolve and offer even more capabilities than they do today.

Increased Intelligence

One significant trend is the move towards greater intelligence in polyfunctional robots. With advancements in artificial intelligence and machine learning, future robots will be able to analyze data faster and make real-time decisions. This improvement will enhance their ability to adapt to changing environments and workflows.

- Enhanced machine learning algorithms

- Improved data analytics capabilities

- Advanced image and object recognition

- Greater adaptability to various tasks

As a result, these robots will seamlessly integrate into industrial processes, making adjustments on-the-fly without human intervention.

Collaborative Robotics

Another trend is the rise of collaborative robotics, also known as cobots. Unlike traditional industrial robots that work independently and require safety cages, cobots are designed to work alongside humans. They can assist workers by taking on repetitive tasks, while humans focus on more complex activities.

This collaboration not only increases productivity but also enhances safety in the workplace. As cobots become more prevalent, their capabilities and cooperation with humans will continue to improve, creating more efficient work environments.

Customization and Flexibility

Future polyfunctional robots will also offer enhanced customization and flexibility tailored to specific industry needs. Companies will be able to modify robots for unique tasks without extensive redesign or reprogramming. This flexibility will allow manufacturers to respond quickly to market changes.

Additionally, the use of modular designs will enable users to swap out components based on task requirements. This adaptability will help businesses maximize their return on investment as they can keep their robots relevant longer.

Overall, the future of polyfunctional robots in automation looks promising, filled with advancements that will shape the landscape of various industries. These trends will ensure that businesses remain competitive while enhancing efficiency and productivity.

FAQ – Frequently Asked Questions about Polyfunctional Robots in Industrial Automation

What are polyfunctional robots?

Polyfunctional robots are advanced machines designed to perform multiple tasks within an industrial setting, enhancing efficiency and adaptability.

How do polyfunctional robots improve productivity?

They streamline operations by handling various functions that would typically require separate machines, thus reducing downtime and resource use.

What challenges come with adopting polyfunctional robots?

Some challenges include high initial costs, integration with existing systems, and ensuring workforce adaptation to new technologies.

What trends are shaping the future of polyfunctional robots?

Future trends include increased intelligence, collaborative robotics, and greater customization options to meet specific industry demands.